Graphite electrodes (GE)

In order to meet the different usage environments of customers, PUKEBEI delivers high-quality products in various forms: Baked electrodes, Blank Electrodes, and finished Graphite Electrodes.

Baked Electrodes

Blank Electrodes

Graphite Electrodes

The maximum production size of UHP graphite electrodes can reach L3000xф800(mm).

Products have high thermal conductivity, low resistance, high strength at high temperatures, stable quality, and long service life. They can meet the demanding needs of modern smelting workshops, and their comprehensive performance reaches the world’s first-class level.

█ Physical Property Data

| Specifications | Bulk Density | Specific Resistance | Flexural Strength |

CTE | ASH | |

| grade | mm | g/cm3 | Ω·m | Mpa | 10-6/℃ | % |

| RP GE | ∅75-∅600 | 1.55~1.65 | 7.0~9.8 | 6.5~9.5 | 2.0~2.5 | 0.3 |

| HP GE | ∅200-∅700 | 1.65~1.72 | 5.4~6.5 | 9.0~15.0 | 1.9~2.4 | 0.2 |

| UHP GE | ∅300-∅800 | 1.66~1.75 | 4.2~5.8 | 9.0~15.5 | 1.0~1.5 | 0.2 |

| Connector nipples of all sizes | 1.78~1.85 | 3.0~4.5 | 20~32 | 0.9~1.7 | 0.2 | |

| Property values represent typical ranges and do not form a guarantee for individual electrodes or nipple. | ||||||

█ Electrode Diameters / Lengths / Weight

| Electrode dia and length(mm) | Dia x length electrodes(inch) | Type of nipple | No. of pieces on one pallet | Avg. single electrode weight(kg) |

Overall dimensions | Avg. weight electrode with nipple (kg) | ||

| ∅ 78x1600 | 3×64 | 45T4N | 65 | 12 | 1700×1014×500 | 800 | ||

| ∅105x1800 | 4×72 | 69T4N | 34 | 26 | 1900×1090x520 | 900 | ||

| ∅135×1800 | 5×72 | 79T4B | 26 | 42 | 1890×1100×640 | 1090 | ||

| ∅155×1800 | 6×72 | 92T4N | 18 | 56 | 2000×1080×510 | 1030 | ||

| ∅205×1800 | 8×72 | 122T4N | 9 | 97 | 2090×1065×500 | 930 | ||

| ∅256×1800 | 10×72 | 155T3N 152T4N |

7 | 150 | 2110×1065×600 | 1150 | ||

| ∅307×1800 | 12×72 | 177T3N 177T4N |

3 6 |

220 | 2135×960×420 2135×960×720 |

710 1420 |

||

| ∅358×1800 ×2100 |

14×72 14×84 |

215T3N 203T4N |

3 | 290 343 |

2150×1100×470 2450×1100×470 |

915 1070 |

||

| ∅409×1800 ×2100 |

16×72 16×84 |

241T3N 222T4N 222T4L |

2 3 |

391 450 |

2175×855×520 2475×1265×520 |

830 1345 |

||

| ∅460×1800 ×2100 ×2400 |

18×72 18×84 18×96 |

273T3N 241T4N 241T4L |

2 | 491 570 651 |

2175×960×570 2475×960×570 2780×960×570 |

1035 1140 1380 |

||

| ∅511×2100 ×2400 ×2700 |

20×84 20×96 20×108 |

298T3N 269T4N 269T4L |

2 | 680 792 886 |

2530×1065×630 2830×1065×630 3130×1065×630 |

1440 1680 1870 |

||

| ∅562×2100 ×2400 ×2700 |

22×84 22×96 22×108 |

298T3N 298T4N 298T4L |

2 | 833 958 1077 |

2550×1165×680 2850×1165×680 3150×1165×680 |

1770 2026 2267 |

||

| ∅613×2100 ×2400 ×2700 |

24×84 24×96 24×108 |

317T4N 317T4L |

2 | 997 1139 1340 |

2550×1265×750 2850×1265×750 3150×1265×750 |

2100 2401 2798 |

||

| ∅663×2400 ×2700 |

26×96 26×108 |

355T4N 355T4L |

2 | 1407 1545 |

2900×1365×800 3200×1365×800 |

3000 3280 |

||

| ∅714×2400 ×2700 |

28×96 28×108 |

374T4N 374T4L |

2 | 1546 1741 |

2900×1470×855 3200×1470×855 |

3290 3690 |

||

| ∅765×2700 | 30×108 | 406T4L | 2 | 1993 | 3225×1565×900 | 4210 | ||

| ∅816×2700 | 32×108 | 432T4L | 1 | 2399 | 3265×860×960 | 2540 | ||

| The electrode length and diameter can be adjusted to your operational conditions. | ||||||||

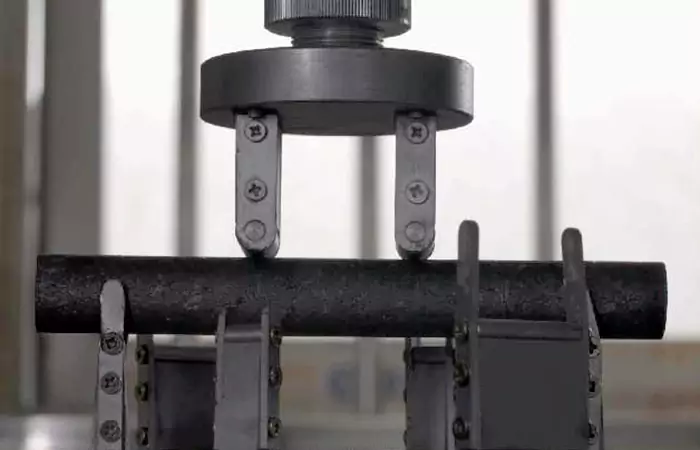

█ Quality Inspection

All products are subject to rigorous testing and control procedures, and graphite electrode consumption can be impacted by many variables during its application. Normally, it can achieve specific consumption below 2kg/ton of steel produced.in order to guarantee a high and consistent quality to its end users.